Environmental Evaluation Using Waste Reduction Algorithm of a Mass and Energy-Integrated Gas Oil Hydrocracking Process

Evaluación Ambiental Usando Algoritmo de Reducción de Residuos de un Proceso de Hidrocraqueo de Gasóleo Integrado En Masa y Energía

Barra lateral del artículo

Términos de la licencia (VER)

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Declaración del copyright

Los autores ceden en exclusiva a la Universidad EIA, con facultad de cesión a terceros, todos los derechos de explotación que deriven de los trabajos que sean aceptados para su publicación en la Revista EIA, así como en cualquier producto derivados de la misma y, en particular, los de reproducción, distribución, comunicación pública (incluida la puesta a disposición interactiva) y transformación (incluidas la adaptación, la modificación y, en su caso, la traducción), para todas las modalidades de explotación (a título enunciativo y no limitativo: en formato papel, electrónico, on-line, soporte informático o audiovisual, así como en cualquier otro formato, incluso con finalidad promocional o publicitaria y/o para la realización de productos derivados), para un ámbito territorial mundial y para toda la duración legal de los derechos prevista en el vigente texto difundido de la Ley de Propiedad Intelectual. Esta cesión la realizarán los autores sin derecho a ningún tipo de remuneración o indemnización.

La autorización conferida a la Revista EIA estará vigente a partir de la fecha en que se incluye en el volumen y número respectivo en el Sistema Open Journal Systems de la Revista EIA, así como en las diferentes bases e índices de datos en que se encuentra indexada la publicación.

Todos los contenidos de la Revista EIA, están publicados bajo la Licencia Creative Commons Atribución-NoComercial-NoDerivativa 4.0 Internacional

Licencia

![]()

Esta obra está bajo una Licencia Creative Commons Atribución-NoComercial-NoDerivativa 4.0 Internacional

Contenido principal del artículo

Resumen

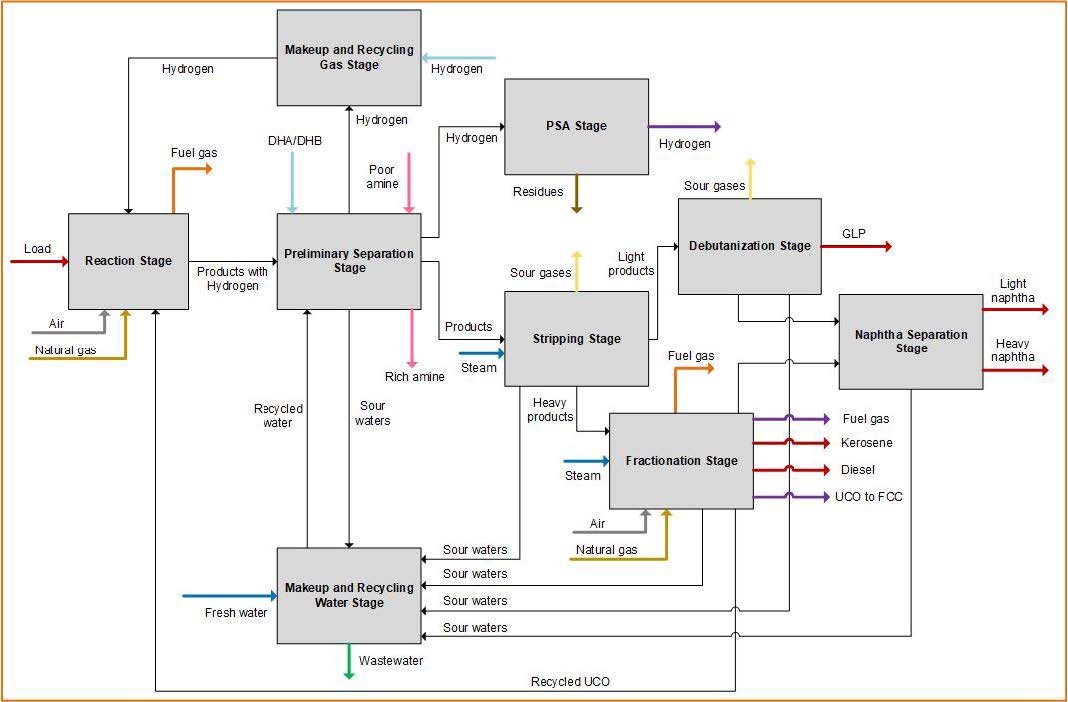

Due to increasing environmental regulations, the chemical industry is evolving towards more efficient production, placing the petrochemical sector in a difficult situation due to its economic and environmental effects. In this regard, it is crucial to perform an environmental impact assessment of refinery processes to balance operational needs with environmental concerns. Fuels such as LPG (liquefied petroleum gas), naphtha, diesel, and kerosene, which are obtained by gas oil hydrocracking process on an industrial scale, are highly efficient, but present environmental problems due to emissions of toxic substances and greenhouse gases. The environmental assessment was carried out to address this challenge, using the Waste Reduction (WAR) algorithm methodology and the WAR GUI® computational tool. Subsequently, the environmental parameters of the chemicals involved in the process were calculated, an environmental impact assessment was performed, and the potential global and category impacts were evaluated, including Ozone Depletion Potential (ODP), Global Warming Potential (GWP), Photochemical Oxidation Potential (PCOP), and Acidification Potential (AP) within the atmospheric impacts, and Human Toxicity Potential by Ingestion (HTPI), Human Toxicity Potential by Inhalation or Dermal Exposure (HTPE), Aquatic Toxicity Potential (ATP), and Terrestrial Toxicity Potential (TTP) within the toxicological impacts. In this way, the environmental performance was analyzed focusing on the potential environmental impact (PEI) using the generation rate and output rate of various fuels in an integrated gas oil hydrocracking process, both from the mass and energy perspectives.

The results show that the process converts low-PEI feedstocks, such as gas oils, into higher-PEI products, such as kerosene, with significant PEI generation in Cases 2, considering products and waste (516,000 PEI/h) and 4, considering products, energy, and waste (519,000 PEI/h). However, due to the mass integration of wastewater effluents, the contribution of the process stages to PEI was reduced considering waste. On the other hand, the large product flow increased PEI per unit time, but reduced PEI per kilogram of product. Now, ATP (Aquatic Toxicity Potential) had the highest toxicological PEI (500,000 PEI/h); while PCOP (Photochemical Oxidation Potential) had the highest atmospheric PEI (36,300 PEI/h). Additionally, the stage that contributes the most to the production of PEI per hour is the preliminary separation stage, reaching 82.03% considering waste and 58.72% considering energy. On the other hand, natural gas was found to have lower environmental impacts compared to liquid (oil) and solid (coal) energy sources. Additionally, toxicological and atmospheric impacts showed moderate PEI values per category (positive and negative), demonstrating that an integrated gas oil hydrocracking process in terms of mass and energy presents better results in terms of environmental impacts, compared to a conventional gas oil hydrocracking plant, contributing to the sustainability of the process. Finally, when comparing this process with others, the integrated gas oil hydrocracking process in terms of mass and energy is more environmentally acceptable than biohydrogen production (12,000,000 PEI/h).

Descargas

Detalles del artículo

Referencias (VER)

Abban, J. P. (2023). Artificial Intelligence Technology Application and Occupational Safety in Downstream Petroleum Industries in Greater Accra [Tesis de maestría, University of Cape Coast]. https://ir.ucc.edu.gh/xmlui

Al-Rubaye, A. H.; Jasim, D. J.; Jassam, S. A.; Jasim, H. M.; Ameen, H. F. M.; Al-Robai, H. A. (2023). The side effect of oil refine-ries on environment: As a mini review. IOP Conference Series: Earth and Environmental Science, 1262(2). https://doi.org/10.1088/1755-1315/1262/2/022024

Brough, D.; Jouhara, H. (2020). The aluminium industry: A review on state-of-the-art technologies, environmental impacts and possibilities for waste heat recovery. International Journal of Thermofluids, 1–2, 100007. https://doi.org/10.1016/j.ijft.2019.100007

Cabezas, H.; Bare, J. C.; Mallick, S. K. (1999). Pollution prevention with chemical process simulators: The generalized waste reduction (WAR) algorithm—Full version. Computers & Chemical Engineering, 23(4–5), 623–634. https://doi.org/10.1016/S0098-1354(98)00298-1

Cardona, C. A.; Marulanda, V. F.; Young, D. (2004). Analysis of the environmental impact of butylacetate process through the WAR algorithm. Chemical Engineering Science, 59(24), 5839–5845. https://doi.org/10.1016/j.ces.2004.06.043

Centeno-Bordones, G.; Labrador, H.; Lara Moreno, G. (2021). Aguas agrias en el procesamiento de crudos pesados: Carac-terización fisicoquímica y prognosis de su impacto ambiental. Revista Digital Novasinergia, 4(1), 115–135.

Douet, J. (2020). The heritage of the oil industry TICCIH thematic study. www.ticcih.org

El-Halwagi, M. M.; Gabriel, F.; Harell, D. (2003). Rigorous graphical targeting for resource conservation via material recycle/reuse networks. Industrial and Engineering Chemistry Research, 42(19), 4319–4328. https://doi.org/10.1021/ie030318a

Fan, Y. Van; Lee, C. T.; Lim, J. S.; Klemeš, J. J.; Le, P. T. K. (2019). Cross-disciplinary approaches towards smart, resilient and sustainable circular economy. Journal of Cleaner Production, 232, 1482–1491. https://doi.org/10.1016/j.jclepro.2019.05.266

FAO. (2019). El apoyo de la FAO para alcanzar los Objetivos de Desarrollo Sostenible en América del Sur – Panorama. Organización de las Naciones Unidas para la Alimentación y la Agricultura.

García-Maza, S.; González-Delgado, Á. D. (2024). Robust simulation and technical evaluation of large-scale gas oil hydro-cracking process via extended water-energy-product (E-WEP) analysis. Digital Chemical Engineering, 13, 100193. https://doi.org/10.1016/j.dche.2024.100193

Gebreslassie, B. H.; Slivinsky, M.; Wang, B.; You, F. (2013). Life cycle optimization for sustainable design and operations of hydrocarbon biorefinery via fast pyrolysis, hydrotreating and hydrocracking. Computers & Chemical Engineering, 50, 71–91. https://doi.org/10.1016/j.compchemeng.2012.10.013

Gonzalez-Delgado, A. D.; Parejo, V.; Herrera, T. (2017). Computer-aided environmental evaluation of bio-hydrogen pro-duction from residual biomass of palm cultivation. Contemporary Engineering Sciences, 10, 773–783. https://doi.org/10.12988/ces.2017.7770

González-Delgado, Á. D.; Ramos-Olmos, M.; Aguilar-Vásquez, E. (2023). Environmental impacts assessment in suspension PVC production process using computer-aided process engineering. Polymers, 15(13). https://doi.org/10.3390/polym15132902

Gruia, A. (2006). Recent advances in hydrocracking. En Springer Handbook of Petroleum Technology (pp. 219–255). Springer New York.

Herrera, T.; Parejo, V.; González-Delgado, Á. (2022). Environmental analysis of avocado (Laurus persea L.) oil production in North Colombia using the waste reduction algorithm. Chemical Engineering Transactions, 91, 235–240. https://doi.org/10.3303/CET2291040

Hoek, A.; Huizinga, T.; Esener, A. A.; Maxwell, I. E.; Stork, W.; Van de Meerakker, F. J.; Sy, O. (1991). New catalysts improves heavy feedstock hydro-cracking. Oil and Gas Journal, 89(16).

Iplik, E.; Aslanidou, I.; Kyprianidis, K. (2020). Hydrocracking: A perspective towards digitalization. Sustainability, 12(17). https://doi.org/10.3390/su12177058

Kaiser, M. J. (2017). A review of refinery complexity applications. Petroleum Science, 14(1), 167–194. https://doi.org/10.1007/s12182-016-0137-y

Kamiya, Y. (1991). Heavy oil processing handbook. RAROP.

Mahmud, R.; Moni, S. M.; High, K.; Carbajales-Dale, M. (2021). Integration of techno-economic analysis and life cycle as-sessment for sustainable process design – A review. Journal of Cleaner Production, 317, 128247. https://doi.org/10.1016/j.jclepro.2021.128247

Petrescu, L.; Cormos, C. C. (2015). Waste reduction algorithm applied for environmental impact assessment of coal gasifi-cation with carbon capture and storage. Journal of Cleaner Production, 104, 220–235. https://doi.org/10.1016/j.jclepro.2014.08.064

Rincón, L. E.; Jaramillo, J. J.; Cardona, C. A. (2014). Comparison of feedstocks and technologies for biodiesel production: An environmental and techno-economic evaluation. Renewable Energy, 69, 479–487. https://doi.org/10.1016/j.renene.2014.03.058

Sammons, N.; Yuan, W.; Bommareddy, S.; Eden, M. R.; Aksoy, B.; Cullinan, H. (2009). A systematic framework to calculate economic value and environmental impact of biorefining technology. Computer Aided Chemical Engineering, 27(C), 2007–2012. https://doi.org/10.1016/S1570-7946(09)70725-4

Speight, J. G. (2011). Production, properties and environmental impact of hydrocarbon fuel conversion. En Advances in Clean Hydrocarbon Fuel Processing: Science and Technology (pp. 54–82). https://doi.org/10.1533/9780857093783.1.54

Sullivan, R. F. (1985). Two-stage catalytic hydrocracking of ITSL oil for jet fuel and naphtha. Preprints-American Chemi-cal Society. Division of Petroleum Chemistry, 30(3), 503–512.

Velásquez-Barrios, A.; Rueda-Duran, C.; Mogollón, E.; Carlos Alvarez, J.; Cardona, R.; Cardona-Alzate, C. A. (2018). Analysis of the environmental impact using the waste reduction algorithm WAR in polypropylene process production by ap-plying grade transitions strategies.

Wu, L.; Liu, Y. (2016). Environmental impacts of hydrotreating processes for the production of clean fuels based on life cycle assessment. Fuel, 164, 352–360. https://doi.org/10.1016/j.fuel.2015.10.017

Young, D. M.; Cabezas, H. (1999). Designing sustainable processes with simulation: The waste reduction (WAR) algorithm. Computers & Chemical Engineering, 23(10), 1477–1491. https://doi.org/10.1016/S0098-1354(99)00306-3

Young, D.; Scharp, R.; Cabezas, H. (2000). The waste reduction (WAR) algorithm: Environmental impacts, energy consum-ption, and engineering economics. Waste Management, 20(8), 605–615. https://doi.org/10.1016/S0956-053X(00)00047-7

PDF

PDF

FLIP

FLIP